DC air compressors provide power to various pneumatic tools in facilities across a range of applications. However, understanding how to use DC air compressors can sometimes be challenging. Here, we provide a step-by-step guide to help you properly use a DC air compressor.

DC air compressors from Oasis can be mounted in a range of locations, including in a truck bed, in a tool compartment of a service body, to the chassis of a vehicle and more. Their compact design allows for easy positioning and installation.

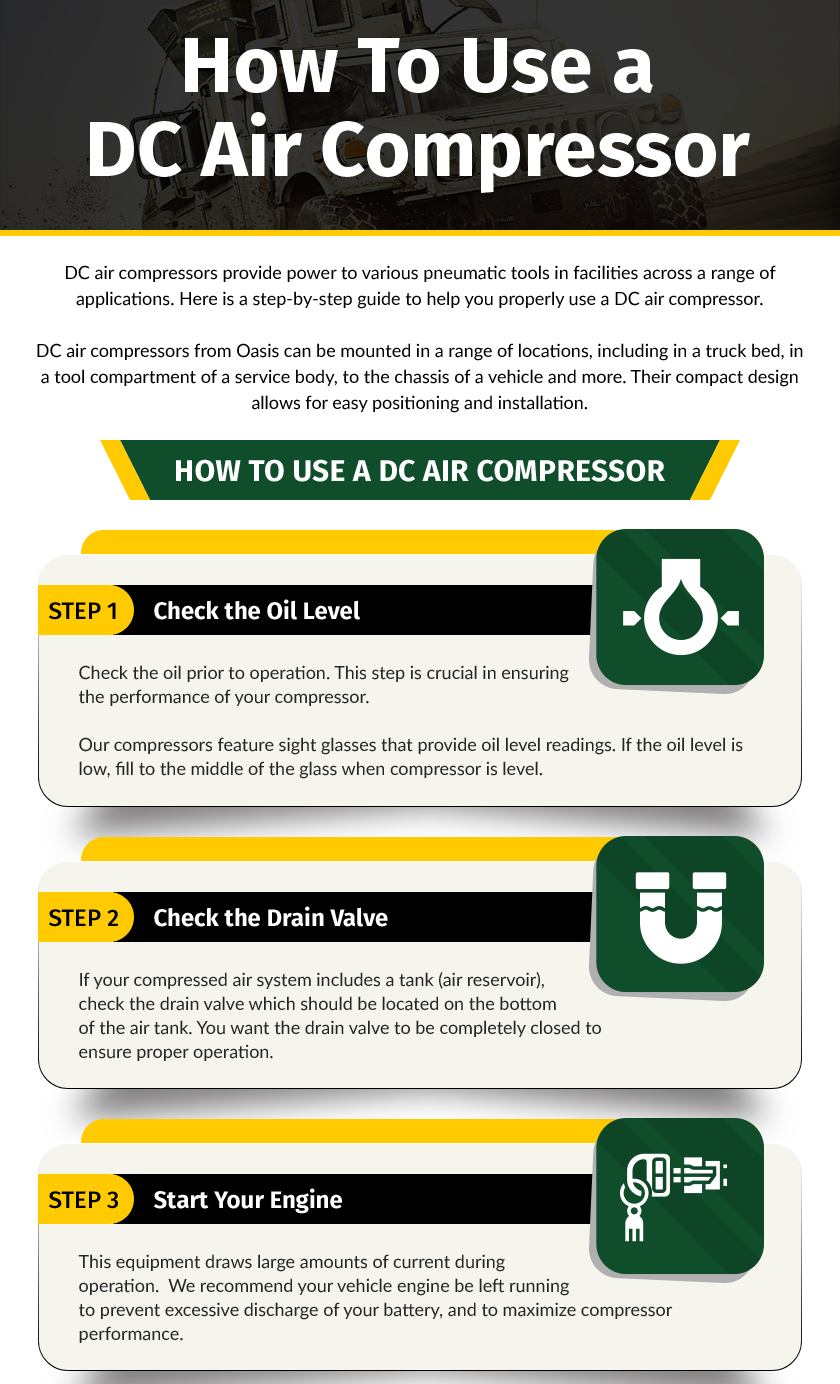

How to Use a DC Air Compressor

To use a DC air compressor correctly, follow these six easy steps:

Step 1: Check the Oil Level

Check the oil level prior to operation. This step is crucial in ensuring the effective performance of your compressor. Our compressors feature sight glasses that provide oil level readings. If the oil level is low, fill to the middle of glass when compressor is level.

Step 2: Check the Drain Valve

If your compressed air system includes a tank (air reservoir), check the drain valve which should be located on the bottom of the air tank. You want the drain valve to be completely closed to ensure proper operation.

Step 3: Start your engine

This equipment draws large amounts of current during operation. We recommend your vehicle engine be left running to prevent excessive discharge of your battery, and to maximize compressor performance.

Step 4: Connect the Air Hose and Desired Tools

Once you’ve set your pressure, you can attach the air hose and tools that will be used for the intended purpose.

Step 5: Remove Excess Moisture

Once you’ve completed the job, remove moisture from your DC air compressor by opening the drain valve at the bottom of the tank and allowing the water and oil to exit.

Step 6: Maintenance Tips

To ensure the performance and efficiency of your DC air compressor, there are several maintenance tips you should follow, including:

- Check the instruction manual often for information regarding care and adjustments

- Check the oil level daily, add oil if necessary

- Regularly check fasteners to ensure they are not loose

- Inspect hoses every few uses to check for holes, tears, and nicks that could negatively affect performance

- Check air intake filter annually, replace element if necessary

- If compressor is exposed to a corrosive environment, all exposed electrical components, especially the motor brushes and motor terminals, should be treated with protective products such as DeoxIT or Fluid Film on a regular basis.

Applications for DC Air Compressors

At Oasis Manufacturing, we offer high-quality, high-performance 12- and 24-volt DC air compressors that can be employed in many different applications, including:

- Maintenance trucks, tow trucks, and service trucks for powering air tools, inflating tires, and more

- Transit buses for air suspension

- Surveillance, news media, and Border Patrol for raising pneumatically operated camera masts

- Agriculture for tires, air tools, and cleaning chaff

- Military for weapons cleaning, inflating tires, and air tools

- Oil and gas mining for the operation of pneumatic valves

All of these and other applications that might require an on-board supply of compressed air would benefit from an Oasis Manufacturing DC air compressor.

DC Air Compressors from Oasis Manufacturing

Oasis Manufacturing DC air compressors are easy to use, portable, and can be mounted on any vehicle to meet the needs of various applications. For more information about our DC air compressors, check out our catalog. You can also contact us and request a quote today to get started on your DC air compressor solution.